![Aditiv Solutions Company Badge - [red_grey 100x100 trans]](https://demowebbuild.co.za/wp-content/uploads/2023/09/Aditiv-Solutions-Company-Badge-red_grey-100x100-trans.png)

Do you need someone to 3D print your parts?

Welcome to our 3D Printing Services page. We do not only manufacture 3D printing machines, but we can also produce your parts for you. We offer a range of industrial 3D printing solutions and can print your parts in metals and nylon. Our 3D Printing Service is designed to cater to the diverse needs of individuals and businesses across various industries.

We specialise in printing parts in ready-to-use engineering materials. Whether you need hundreds of parts for your production requirements, or just a once-off, we’d love to help. Our clients range from hobbyists to Aerospace manufacturing companies.

With our cost-effective, scalable services, you can get access to high-end 3D printed parts. Simply send us your CAD files (3dprinting@aditiv.co.za) or upload them online to get an instant quote.

Explore our services and allow us to streamline your 3D printing production.

(…and one day, when when you are ready, head over to our machine section to buy your own metal printer.)

Why use 3D Printing as a Service?

Access to Advanced Technology

Explore the latest in 3D printing tech and materials. Get your hands on technology that’s not easily available elsewhere.

Maintenance-Free Printing

Enjoy hassle-free 3D printing. We take care of all maintenance, ensuring you get consistent, high-quality prints every time.

Cost-Efficient 3D Printing

Access cutting-edge 3D printing technology without the upfront costs. Save your budget for the parts you need.

Focus on Your Goals

Let us take care of the technology while you concentrate on your core competencies, streamlining your operations.

Scale Your Projects

Whether you need one prototype or a large batch of parts, our scalable service has you covered. No limitations, no worries.

Risk-Free Printing

Eliminate the risk of outdated equipment or costly repairs. We ensure your 3D printing needs are met without worry.

Case Studies

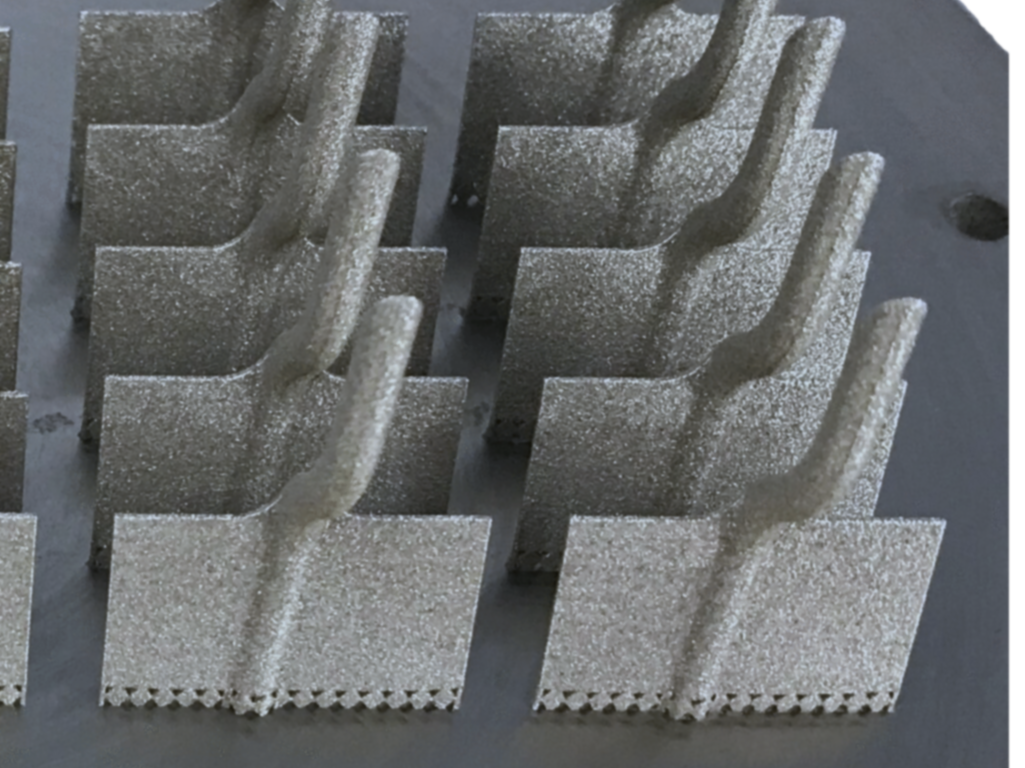

Machine Components

In the machine-building industry, designers are faced with the design of many unique components to make up a single system. For each part, the designer needs to take the manufacturing process into consideration which can pose serious design limitations.

Often, tooling is required to manufacture many of the parts in a machine, which can add severely to the cost and lead time of the project. The machine-building industry typically has low manufacturing volumes and processes like injection moulding and casting are not viable at these production rates.

3D printing (in engineering materials) is becoming a commonplace solution in the machine-building industry for relatively small parts and for complex components.

Read more about how we implemented 3D-printed parts on our own HYRAX...

The HYRAX metal 3D printer makes extensive use of 3D printing. More than 150 parts (80 unique part numbers) on the HYRAX are 3D printed in engineering materials and installed on every machine. 3D parts include funnels, housings, nozzles, knobs, brackets, covers, handles, cams and an array of other components.

Why was 3D printing the chosen manufacturing solution for this application:

- Engineering materials could be used, such as Nylon and 316 SS, yielding excellent properties and long service life.

- Huge non-recurring cost saving (50+ injection moulding/casting tools eliminated)

- Complicated parts could be designed, with few manufacturing limitations to consider.

- In many cases, multiple parts were combined into a single component, reducing processing steps, storage overheads and tolerance build-up.

- Fast turnaround time for getting new parts produced and tested.

- Manufacturing lead time is short (~7 days), so low stock levels can be maintained.

- Design changes are easy since no tooling is required and parts are produced just-in-time.

- Aesthetic designs, with pleasing curves and embossed features, could be implemented, without adding to the manufacturing cost.

These machine components have low production volumes (dozens per year). By 3D printing them, not a single injection moulding tool is required.

A Chess Set was printed in 316 Stainless Steel as a high-value gift.

Luxury goods

An interesting application for metal 3D printing is the production of luxury goods. These are typically artistically designed custom components. We have had clients for a wide array of parts including detailed chess sets, high-value pens, knife handles, “sculptures”, trophies and a host of other applications.

Reasons for printing these include:

- High level of detail can be achieved

- Extremely complex geometries are possible

- Once-off or custom parts can be produced

- Excellent mechanical properties

Jigs and fixtures

A common requirement that we face is for the production of jigs, fixtures, assembly tools and dummy components.

These parts are normally fairly complicated and difficult/expensive to manufacture with traditional methods. They typically need a long service life and also require a good manufacturing tolerance and high stiffness. Nylon 12, produced on a powder bed fusion process, has proven an excellent choice for these parts.

Applications include:

- Drill guides for complex manufacturing operations

- Inspection jigs and Go/No-go tools

- Dummy parts to assist with assembly operations when the real component is not available, damage sensitive or expensive.

- Assembly/testing tools (for example automated PCB test jigs.

A fitment jig was produced to make the assembly of several components easier.

These guides are for an old paper binding machine that is not supported anymore. By printing these in stainless steel, the machine life was extended by years.

Replacement parts

We are regularly approached by clients to produce replacement parts. We’ve printed replacement parts for everything from machinery in the paper production industry to automotive spares.

We found the most common reasons for needing to 3D print replacement parts (instead of sourcing them from an OEM) includes:

- Older components that are not in production anymore (out-of-service)

- Urgent spares with long lead times

- When a small part needs replacement, but is only available as part of a larger assembly.

Product field-testing

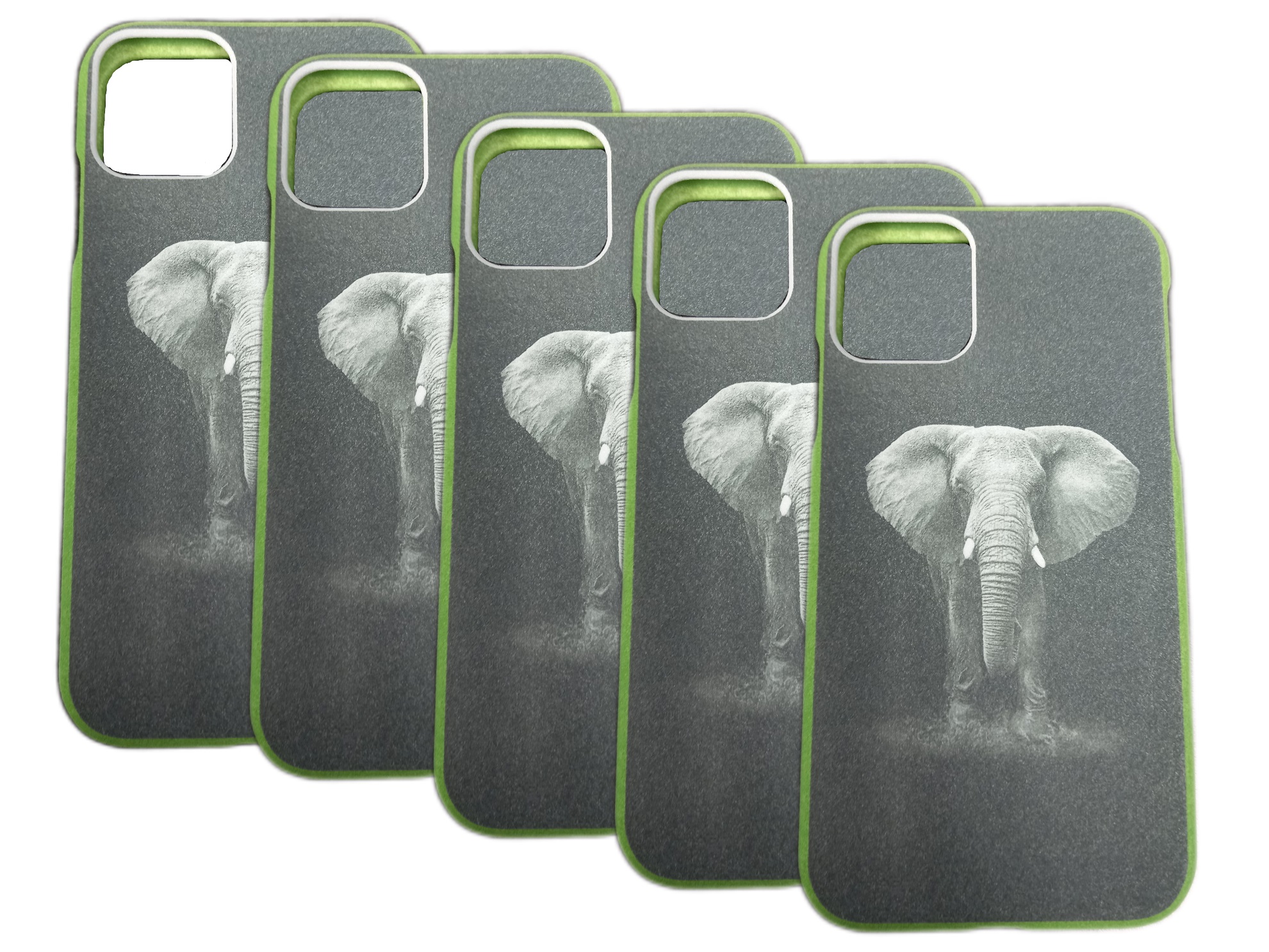

For newly developed products, the initial field-testing can prove a costly exercise. After prototyping, most companies perform a short-batch production to get a few hundred products in the field for real-life testing. Often, the result of field-testing yields some design changes before mass manufacturing can commence, which may result in new tooling requirements.

3D printing in Nylon is commonly utilised to produce the first few hundred products for field testing, before companies commit to injection moulding tools for mass manufacturing.

Why Nylon?

- Nylon is produced on the Powder Bed Fusion process which yields superior results over other 3D printing process

- Good dimensional accuracy and uni-directional mechanical properties

- High toughness and good wear properties

- Resistant to many oils, greases and fuels

- 3D printed parts can be machined, tapped and painted

Consumer goods can be printed to test in real life conditions.

The housings for the PAT Machine Interface get printed from Nylon PA-12 and used as production equipment.

Production parts

One of our customers prints housing from Nylon PA-12 for production purposes for their equipment.

The specific project is for EDC/Mine Safe and it is a PAT machine interface that is the link between the PAT L9 collision avoidance system and machine control system.

Some of the benefits of using 3D Printing for production is:

- No tooling cost.

- Any machine interface or PCB change can influence the housing and this gets mitigated by changing the housing design “on the fly”, and then just printing the new revision.

- Just-in-time batch (low to medium volume) manufacturing.

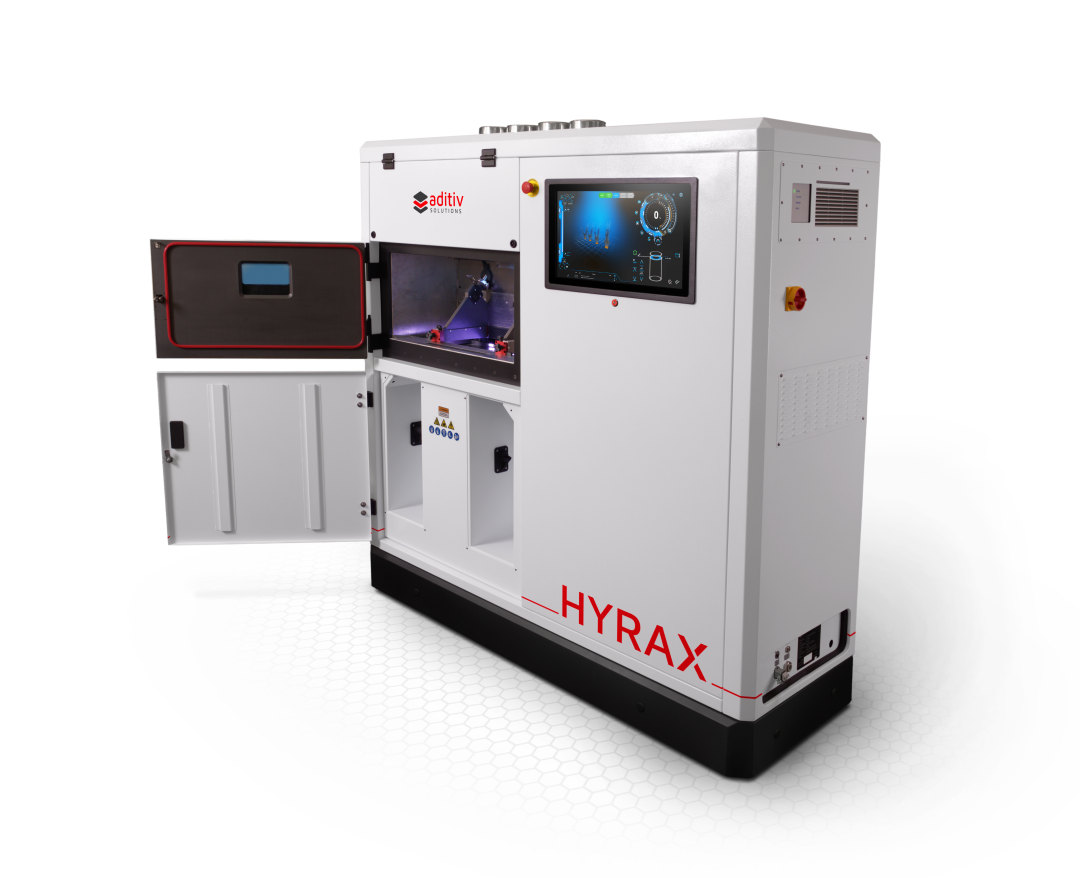

Our 3D Printing Service Machines

Aditiv Solutions HYRAX

Our HYRAX metal 3D printer, can print in a range of metals, yielding excellent mechanical properties.

Want to find out more about the HYRAX, or if you are interested in buying your own, contact us now.

HP Jet Fusion 5210 3D printer

This 3D printer manufacture parts in Nylon 12, a versatile material used to print durable and intricate parts. Almost any geometry can be produced and parts have good dimensional accuracy.

Used for final parts and prototypes.

HP Jet Fusion 580 3D printer

This 3D printer manufacture with Nylon 12 parts in full colour. The technology is more expensive than our standard Nylon 12 parts and is mostly used for prototypes where colour is important.

Application Areas and Industries

3D printing opens up a world of possibilities. While it’s true you can’t 3D print absolutely everything, there’s a universe of applications where it shines, transforming your approach to design, products, and solutions – for you and your customers.

You can use 3D printing to craft stunning art, engineer cutting-edge solutions, revolutionise medical devices, and so much more. These ideas are just the tip of the iceberg (if only the designers of the Titanic had access to 3D printer technology…), designed to ignite your creative spark and inspire limitless innovation.

Ready to explore the endless horizons of 3D printing? Let’s turn your ideas into reality!

General engineering

- Brackets

- Enclosures

- Complex piping

- Valves

Industrial design

- Prototypes

- User acceptance testing

- Field trails

- Low volume production

Consumer goods

- Sporting goods

- Luxury goods

- Arts and crafts

- Gaming models

Energy and Power Generation

- Impellers

- Turbine blades

- Internal cooling

- Blisks

Medical and Dental

- Implants

- Surgical tools

- Drill guides

- Crowns & partial dentures

Aerospace

- Light-weight brackets

- Complex ducting

- Engine components

- Waveguides

Automotive

- Manifolds

- Valve stems

- Interiors

- Customisation